SERVICES

ISI has experience in all types of welding inspection using a variety of Non-Destructive Methods as well as Destructive Methods. You can contact us to assist you during any stage of your project, from concept to completion.

STEEL ERECTION INSPECTION

We have experienced AWS and ICC certified inspectors available who routinely inspect welded structures for various fabrication facilities and state and local agencies.

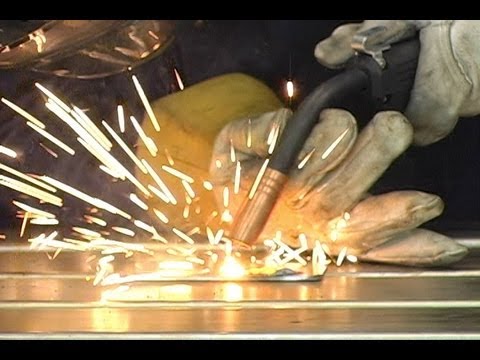

WELDING INSPECTIONS

Our experienced staff of technicians and inspectors are versed in all facets of welding procedures and processes with the ability to inspect and test in accordance with many code requirements. Contact us if you need a quote or assistance with welding on your project.

WELDING CONSULTING

Our team of inspectors can help you identify or establish procedures to meet your specific requirements. We can also aid in determining which weld procedures you may need or which welding certifications your welder may need in order to meet specific job requirements.

INSPECTION CONSULTING

Contact ISI to assist you in establishing specific inspection criteria for your project. We can assist you in determining which codes or inspections may be necessary for your project.

BRIDGE INSPECTION

We have worked in cooperation with engineering contractors inspecting bridges for CDOT and RTD. We have experience with Pedestrian bridges, Fracture Critical, Pin & Hanger connected, Pin & Eyebar, Pin Connected Trusses, Steel Arch and Suspension bridges.

STEEL FABRICATION INSPECTION

Our team of certified inspectors are available to monitor and inspect your fabrication throughout the fabrication process to assure job compliance. We can assist with every step of fabrication from material traceability, cutting, beveling, fit-up, welding and dimensioning.

WELDING PROCEDURES

Our inspectors can help you determine or create which welding procedure you need to comply with your current code requirements or job specifications.

WELDER QUALIFICATION

We have the ability to qualify welders onsite or at our facilities using Non-Destructive methods and Destructive methods. Our team will generate and maintain your qualifications electronically and physically for various codes such as API, AWS and ASME.

Oil & Gas Transmission

ISI provides independent third party Visual, NDE – RT, MT, PT, UT, UTT, PAUT, Fitness for Service Inspections. Project Management for the owners that utilize Chief, Environmental, Welding, Coating and Utility Inspectors. Our Inspectors are certified in accordance with API, AWS, ASNT, NACE and other national standards.

TANK INSPECTION

We have certified API 650 inspectors for tank inspections as well as laser scanning to meet critical tolerances and requirements. We can also perform many NDE tests for code compliance including Xray, Dye Penetrant, Magnetic Particle, Ultrasonic, Visual and Magnetic Flux Leak Inspections.

Certified Tractel Training

We are a certified Tractel training company. We can train and certify your staff to meet Tractel requirements for Evacuation and Rescue procedures in the Wind Turbine industry.

BOLT INSPECTION AND TESTING

We can test the tension of Hex Bolts, Tension Control Bolts, Studs, Anchor Bolts and Lock Nuts in accordance with AISC/RCSC using our portable Skidmore machine. Our inspectors can verify that your bolted connections meet specified torque requirements.

FIREPROOFING INSPECTION

Our inspection team can assist with Spray-Applied Fireproofing and Intumescent Paint inspections. Thickness tests to determine correct thickness is achieved per UL designs specified. Adhesion and Cohesion testing to assure Spray-Applied materials were mixed and applied to manufacture specifications.

QUALITY SURVEYS & AUDITS

We can perform site surveys or audits to ensure your project is meeting code requirements or contract specifications. We can assist your current inspectors with ongoing site analysis.

BORESCOPE INSPECTION

ISI’s experienced inspectors use a variety of remote visual inspection equipment to inspect and evaluate critical operations. Types of services we offer with Borescopes are Boiler Inspections, Pipe Inspections, Turbine Inspections, Wind Turbine Gearbox Inspections, Tank & Pressure Vessel Inspections as well as Foreign Material retrievals.

METALLURGY

ISI works closely with local Metallurgists to certify or test materials. Contact us if you need chemical analysis, mechanical property evaluation, corrosion resistance properties or electrical conductivity testing and we can provide you with answers.

MAGNETIC FLUX LEAKAGE INSPECTION

ISI uses Magnetic Flux Leakage (MFL) to detect corrosion and pitting in steel structures including flat bottom tank floors and piping.

BRIDGE PIN TESTING

ISI has been working with the Colorado Department of Transportation (CDOT) and the Regional Transportation District (RTD) for many years performing Ultrasonic inspections on critical bridge pins to assure material integrity.

QUALITY ASSURANCE / QUALITY CONTROL

We have experienced AWS and ICC certified inspectors able to provide you with in process welding inspections or we can help oversee a project to ensure you’re meeting contract specifications and code requirements.

FITNESS FOR SERVICE

Contact ISI to assist you in determining your products fitness for service. We can perform tests on your equipment to aid your engineers in compiling data to distinguish between acceptable and unacceptable flaws.

DRONE INSPECTIONS

We employ FAA certified pilots to perform various inspections using a range of different cameras with zoom and thermal imaging capabilities. Our services include Photogrammetry, Site Surveys, Stock Pile Volumes, 3D Imaging, Solar Panels, Wind Turbines, Bridges, and many more.

HIGH DEFINITION LASER SCANNING

We use the latest laser scanning technology from Trimble to do site surveys and inspections. Our team can scan storage tanks for code compliance or As-Builts. We can also aid in site surveys and deliver the scans electronically to import into many types of engineering software such as Autodesk.